- Home |

- About Us |

- Contact Us |

中文

中文

中文

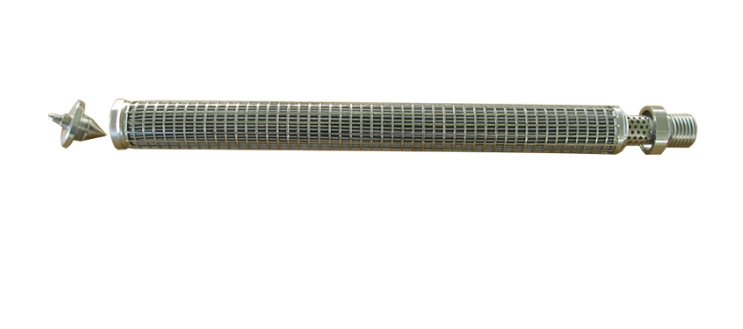

中文 Sintered felt filter Cartridges :

Characteristic:

1 large filtration area, long service life

2 strong capacity, high filtration accuracy, slow pressure rise, long replacement cycle

3 high porosity and excellent permeability, low pressure loss, large flow

4 can clean regeneration, can be used for many times

5 can be customized according to user requirements, such as corrugated, cylindrical shape

Product overview:

Sintered felt filter is made of metal fiber sintered felt made into filter material processing, metal fiber sintered felt with the diameter of the metal fiber micron by non-woven paving, stacked and high sintering temperature, which is composed of layers of different aperture forming holes of different gradient, quantity of pollutants can be controlled by filtering accuracy and extremely high. To maintain continuous filtration filter cloth and a 3D mesh, porous structure, high porosity, large surface area, pore size distribution characteristics. Therefore, metal fiber sintered felt effectively overcomes the defects of metal NetEase blocking, easy to damage, make up the powder filtering products is fragile, lack of the flow of small, solve the filter, filter cloth are not resistant to high temperature and pressure problems. Therefore, metal fiber with excellent filtering performance, high temperature resistance, ideal corrosion resistance, filter material with high precision.

Characteristic

1 large filtration area and long service life

2 strong capacity, high filtration accuracy, slow pressure rise, long replacement cycle

3 high porosity and excellent permeability, low pressure loss, large flow

4 can clean regeneration, can be used for many times

5 can be customized according to user requirements, such as corrugated, cylindrical shape

Application scope:

1 filtration and purification of polymer melts in chemical industry

2 dust removal in high temperature environment

3 filtration of various high temperature corrosion liquids in petrochemical industry

4 mechanical equipment in a variety of hydraulic oil, lubricating oil precision filtration

5 medicine, biology, food and beverage in a variety of liquid clarification filtration